Creating products that touch lives. Brownlie Design develops products for many industries including the medical, consumer, energy, heavy equipment, and industrial markets. For decades clients have come to rely on our leading edge aesthetic and technical expertise. Our commitment to ergonomic design principals, innovative functionality and cost effective manufacturing solutions have remained the hallmark of our work from day one.

Offering a fresh perspective. It all begins with identifying client and user needs. With a variety of methods at our disposal, we’re able to uncover the opportunities and insights our clients need to gain a competitive edge and build brand success. The customer is a valuable resource for determining current product issues, operator needs, product usage, behaviors and brand loyalty motivations. What was known yesterday may be outdated today. We benchmark leading product competitors worldwide to help identify design opportunities and unmet market needs. We analyze and test materials to ensure that a product meets or exceeds the relevant performance standards. Our due diligence sets the stage for enhancing global brand identity, while satisfying market goals.

- Competitive Product Analysis

- Cost Analysis

- Agency Test Requirements

- Environmental Considerations

- Ergonomic Analysis

- Corporate Branding & Identity

- Patent Research & Application

- User Input

- Engineering Input

- Marketing Goals

- Internal Component Requirements

- Manufacturing Processes

- Material Selection

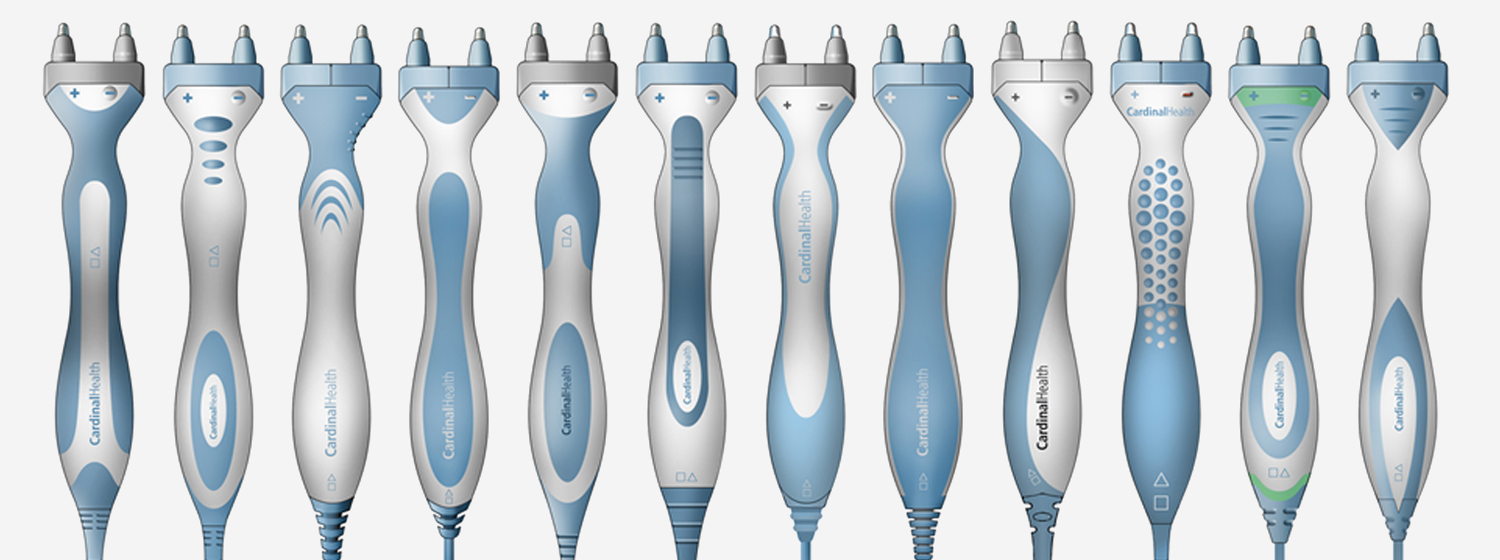

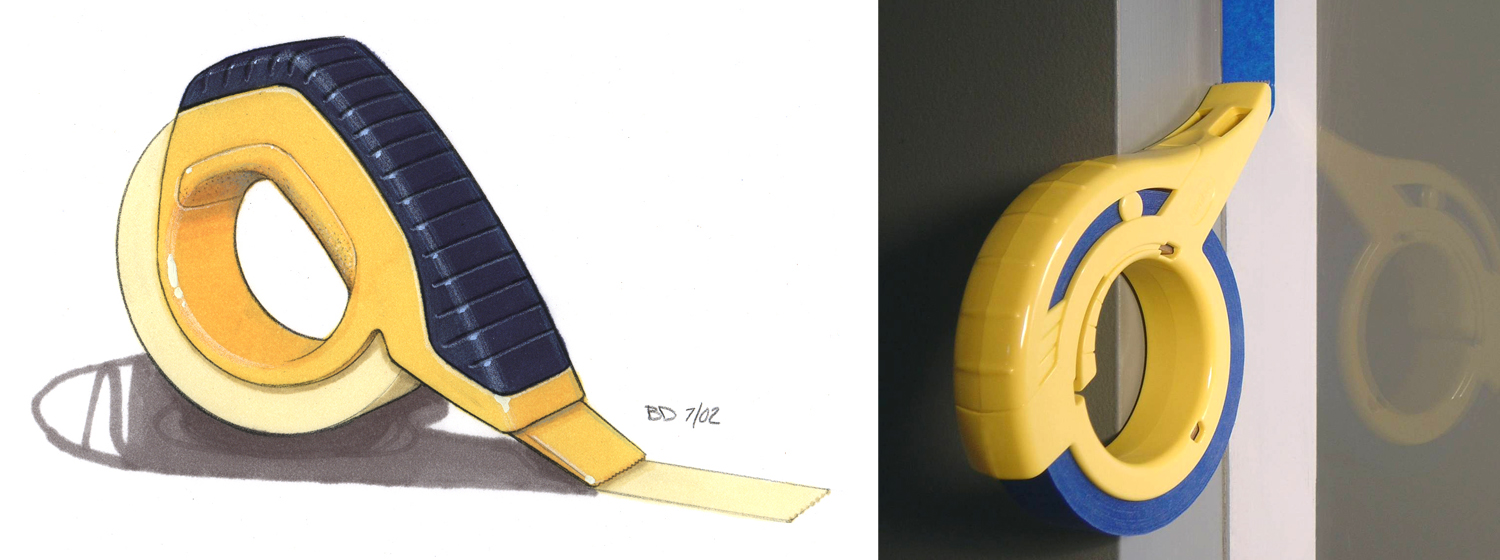

Blue sky, grounded in reality. Our concept design process is a fully engaged effort to define opportunities and solutions for your product. Research paves the way for brainstorming and idea generation. Through idea sketches and CAD layouts we leverage our creative resources to generate an array of appropriate options that work within the manufacturing capabilities, goals and budgets of our clients. Collaborating closely with our key stakeholders, concepts are refined through appearance, rendering, analysis, ergonomic, and CAD modeling, providing visualization tools that empower key product decision making.

- Design Renderings

- Appearance Models

- Ergonomic Study Models

- Photorealistic Renderings

- Creative Brainstorming

- Ideation & Sketching

- 3D Form Studies

- 3D CAD Modeling

Optimizing the user experience. Considering the human body and mind at every step of development is integral to our design process. Observations that incorporate ergonomic measuring, modeling, and testing establish the product’s parameters for comfort and comprehension, reducing fatigue and operator error. Throughout the process a wide range of user profiles and perceptions are taken into account to ensure the products we develop lead their markets in user comfort and safety.

- Field Observations

- Client Interview

- User Testing

- Focus Groups

- 3D CAD Ergonomic Modeling

- Ergonomic Test Models & Fixtures

- GUI Storyboarding

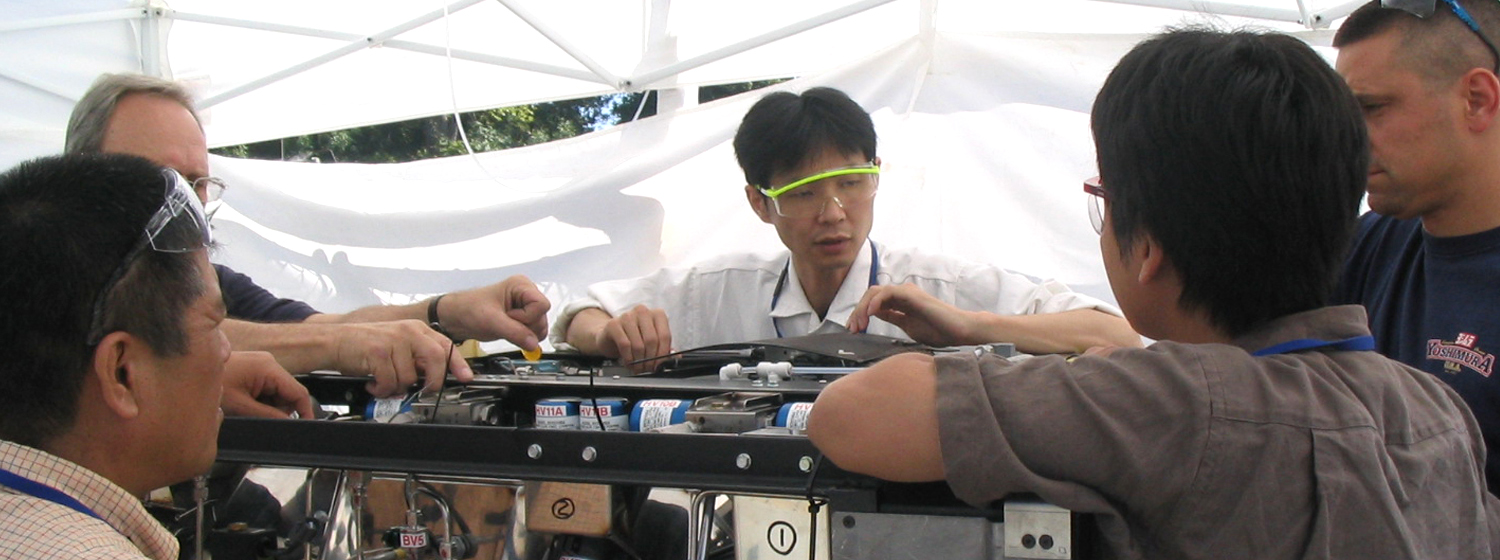

Iterate fast and learn quickly. At every stage of development, prototypes help us explore and understand all aspects of a product's design. Our in-house 3D printer allows us to iterate early and often providing a high level of form and functional refinement. Through rapid prototyping, we can quickly verify a design's ergonomic attributes and aesthetic features. Decisions in refining the components for the assembly process lead to improved manufacturability and lower production cost.

- Composite Molds

- Limited Run Injection Molding

- Formed Sheet Metal

- Metal Castings

- CNC Machining

- Vacuum Form Tooling

- Cast Urethane

- In-house 3D ABS Printing

- FDM

- Appearance Modeling

- Engineered Breadboards / Proof-of-Concept

- Stereolithography

- Selective Laser Sintering (SLS)

Your success depends on it. Our design team works to insure that initial design requirements meet rigorous product specific tests. Verification testing results are used to drive the final product development, and ramp-up for manufacturing.

We select the most suitable materials and simulate repetitive operating conditions to comply with industry specific regulations and specifications. Our reputation and your success rest on noteworthy product reliability and performance. Beyond our strict internal accountability standards, we are committed to satisfying U.S. and overseas regulatory requirements for design and manufacturing protocol.

- Material Suitability

- Manufacturing Review

- Accelerated Life Testing

- Design for Assembly

- Performance Testing

- Agency Approval

- Mold Flow Analysis

- Structural Analysis

Where the rubber meets the road. With a design prototyped and tested, final tweaks to 3D files are made. We work with your preferred vendors or can suggest highly qualified suppliers. Our collaboration with vendors ensures our designs are optimized to meet your production schedule and cost goals.

- Final 3D CAD Modeling

- 2D Documentation

- Production Quotes

- First Part Inspection

- Vendor Liaison