CLIENT

Transonic

MISSION

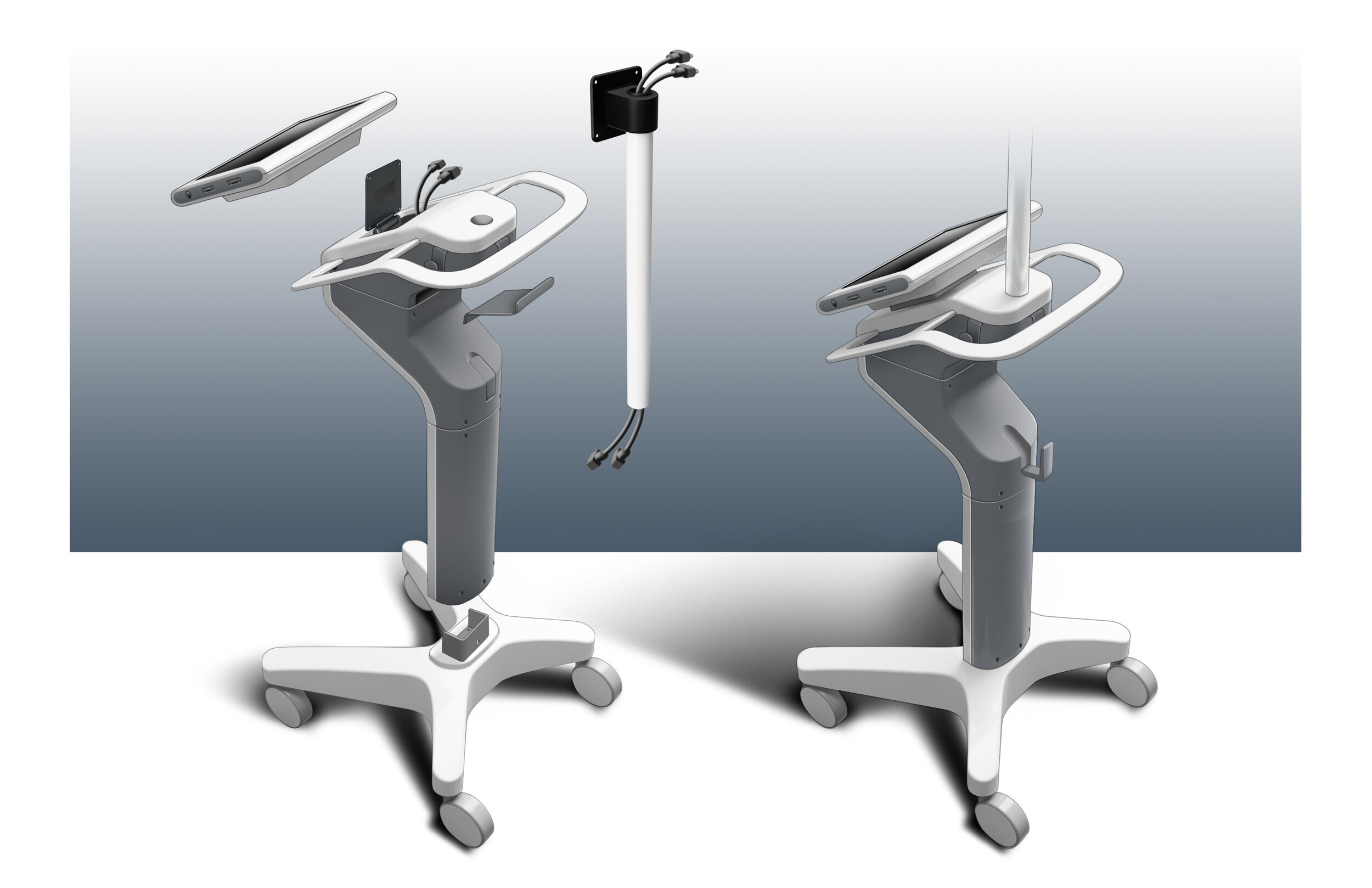

Create a leading-edge aesthetic and ergonomic design for a next-generation flowmeter and cart that would be smaller, lighter, and able to meet the configuration requirements of surgical suites around the world.

USER RESEARCH

PRODUCT AESTHETICS

UI DESIGN

3D CAD MODELING

PROTOTYPE CONSTRUCTION

PRODUCTION DESIGN

USER RESEARCH

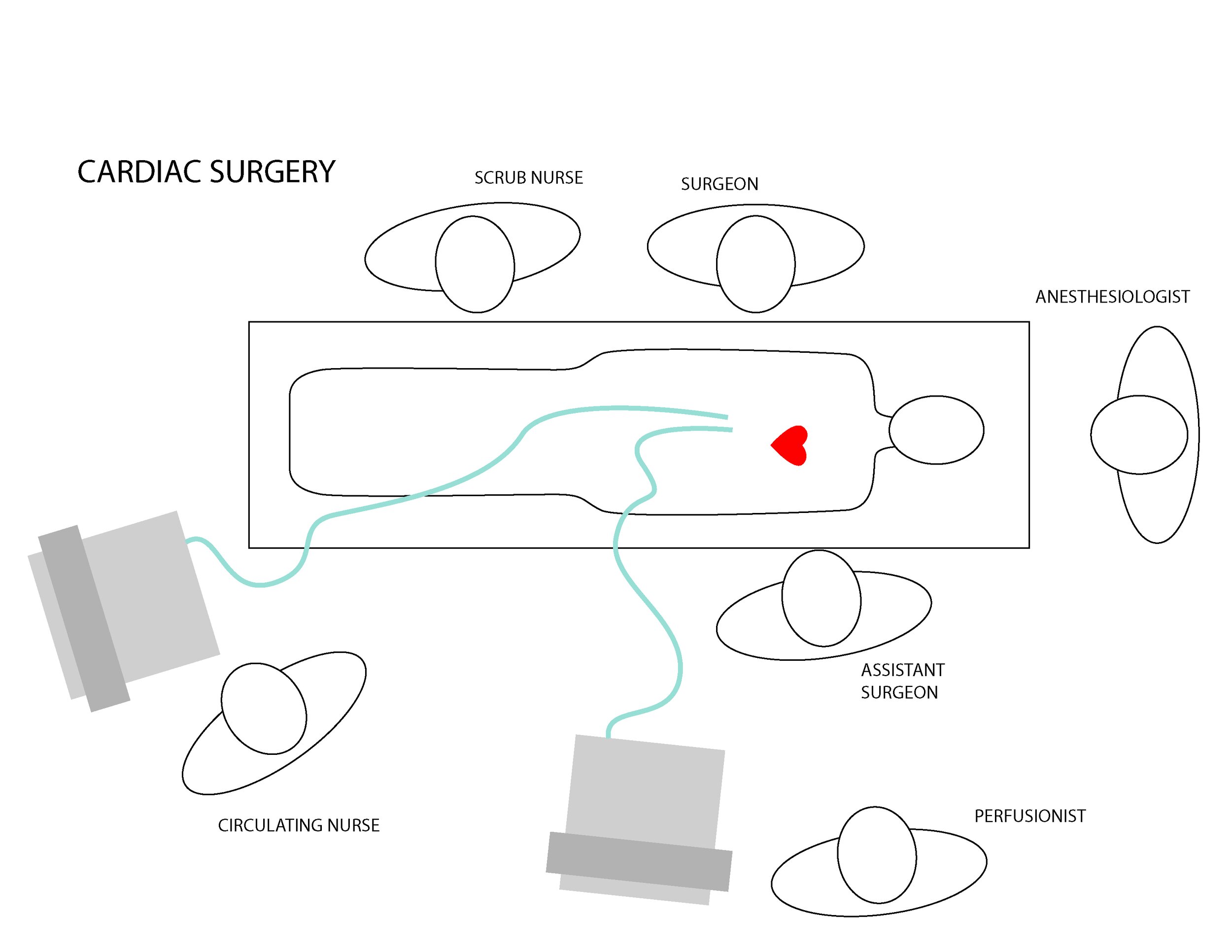

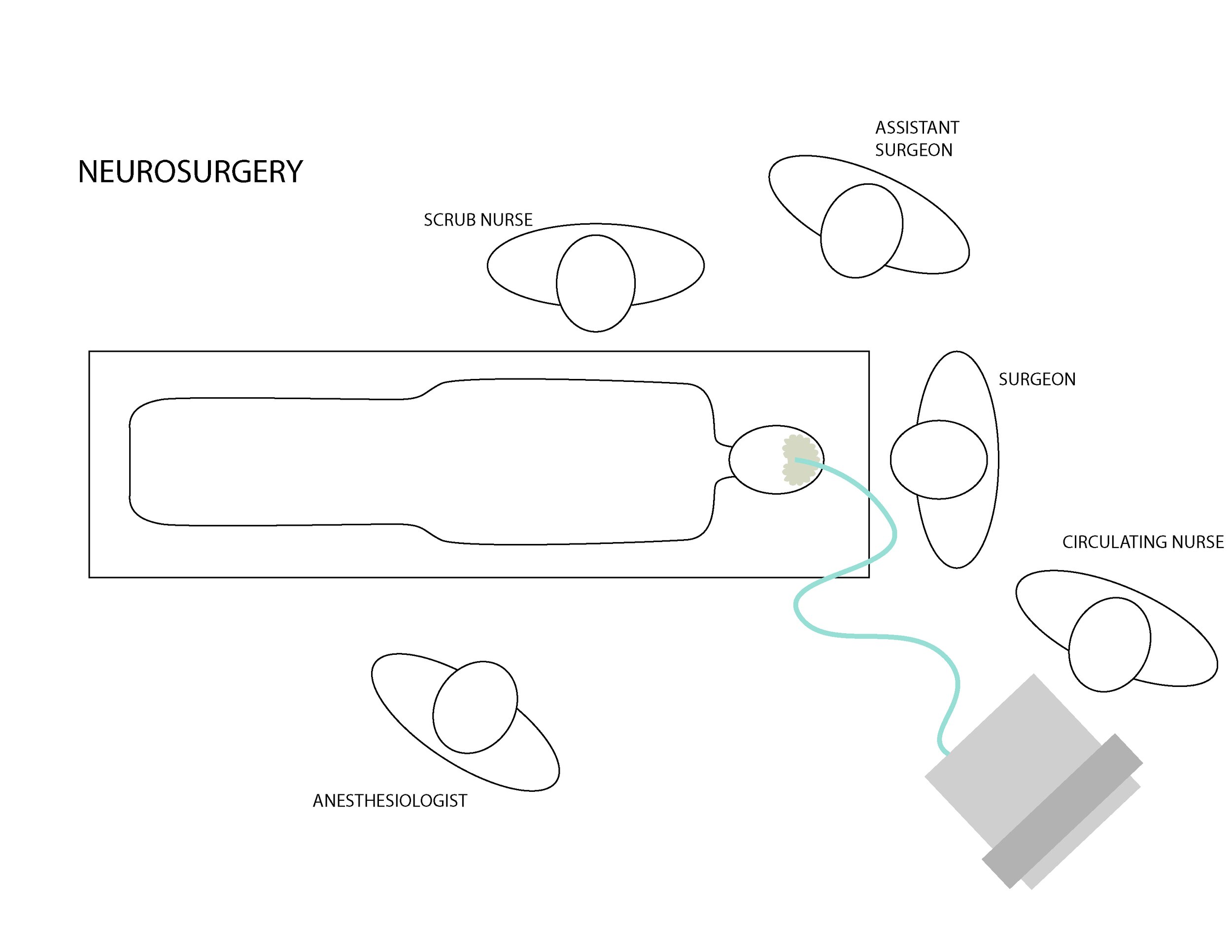

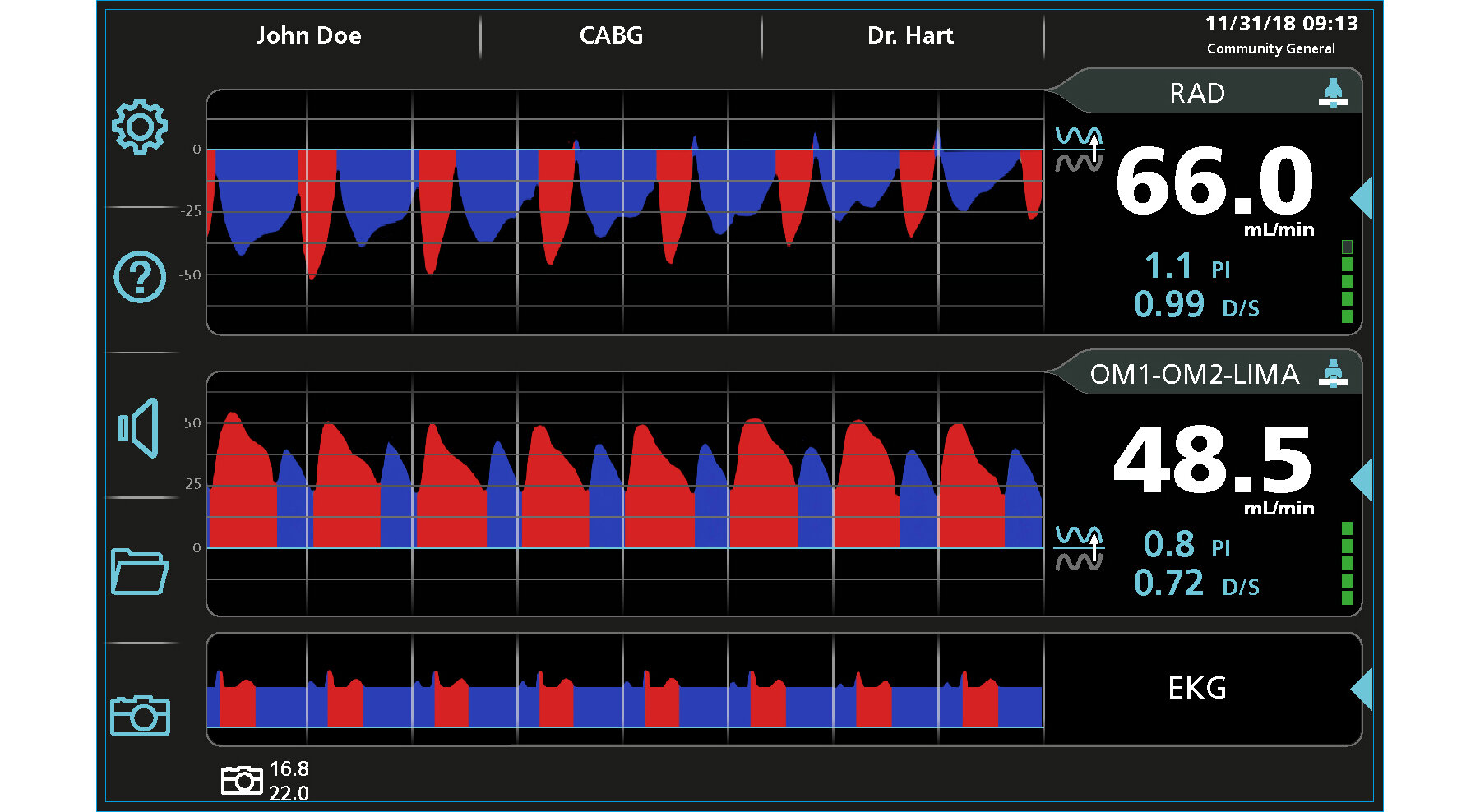

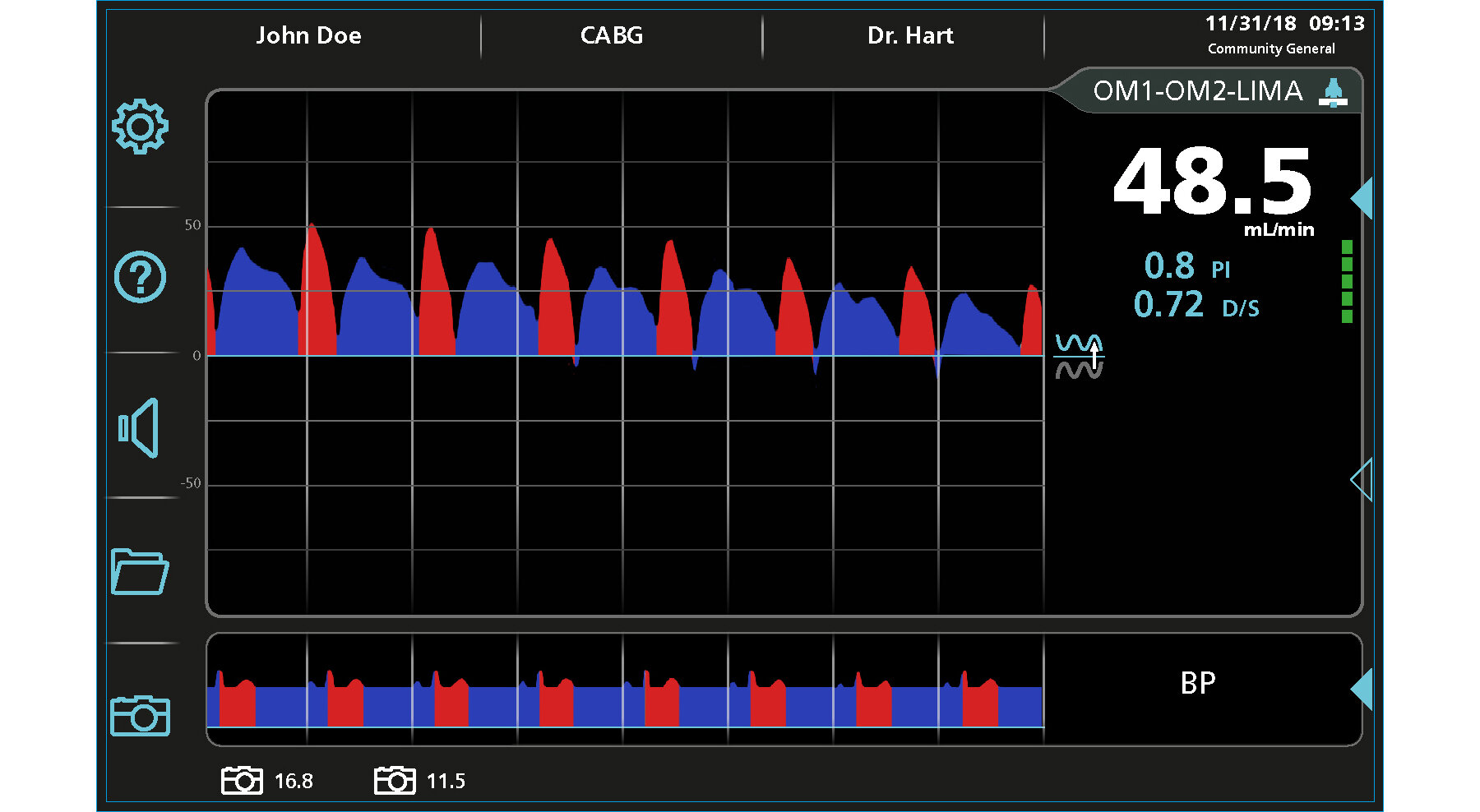

Brownlie Design teamed up with RMS, our market research partner for a thorough review of Transonic’s current flowmeter, a device for measuring blood flow in arteries during surgery. Interviews with surgeons, nurses, and perfusionists, as well as with technicians in charge of maintenance, helped us to better understand their needs and concerns. Our observations as designers often led to further insights.

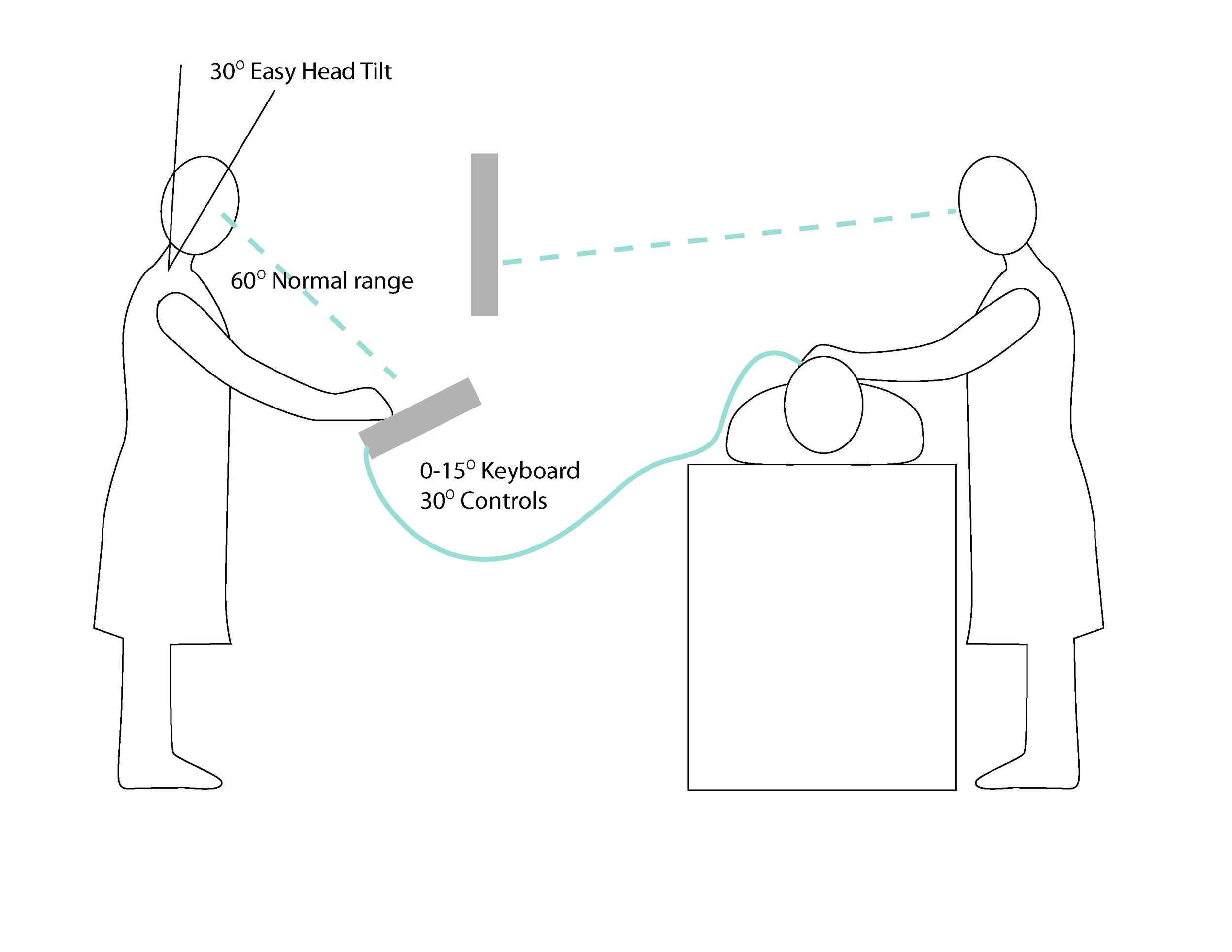

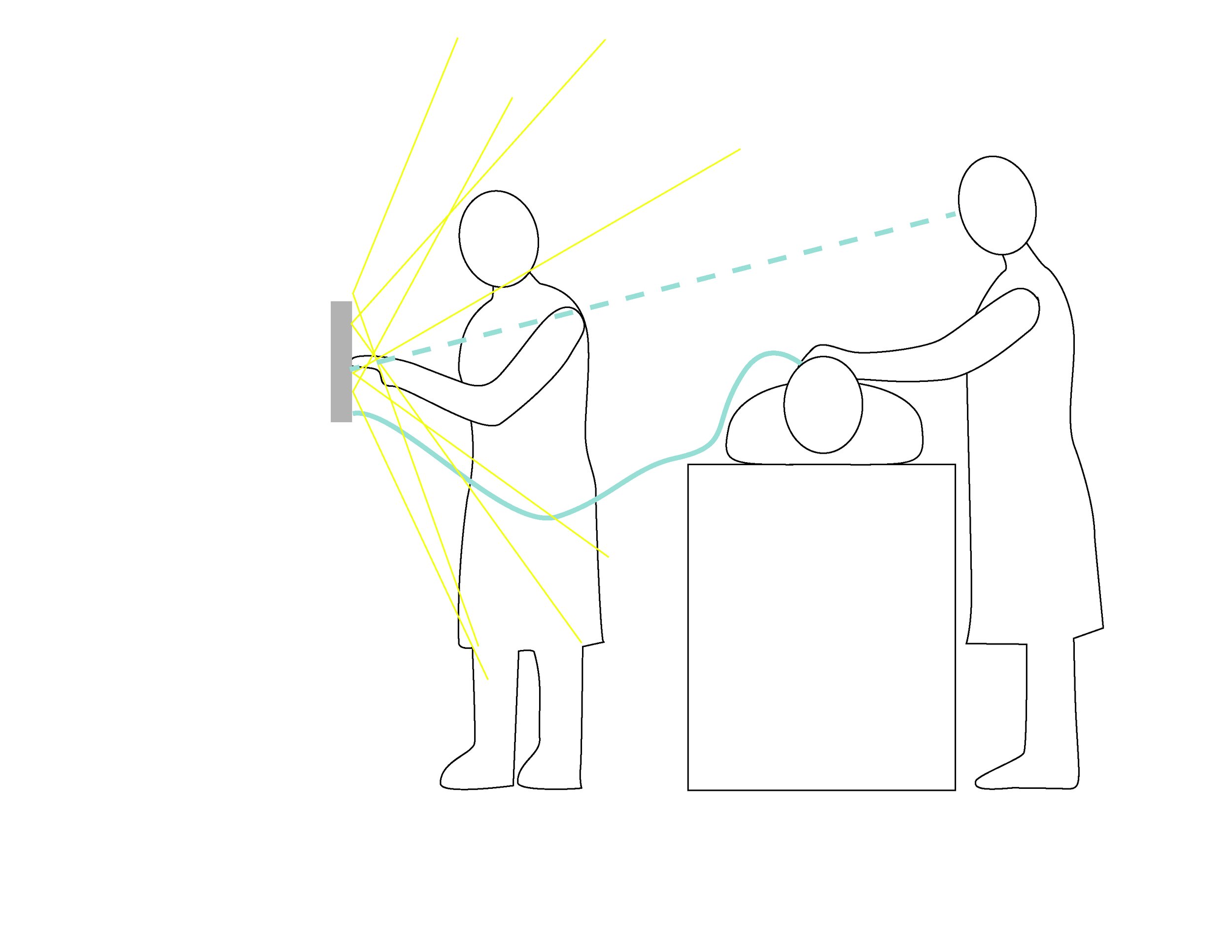

ERGONOMICS

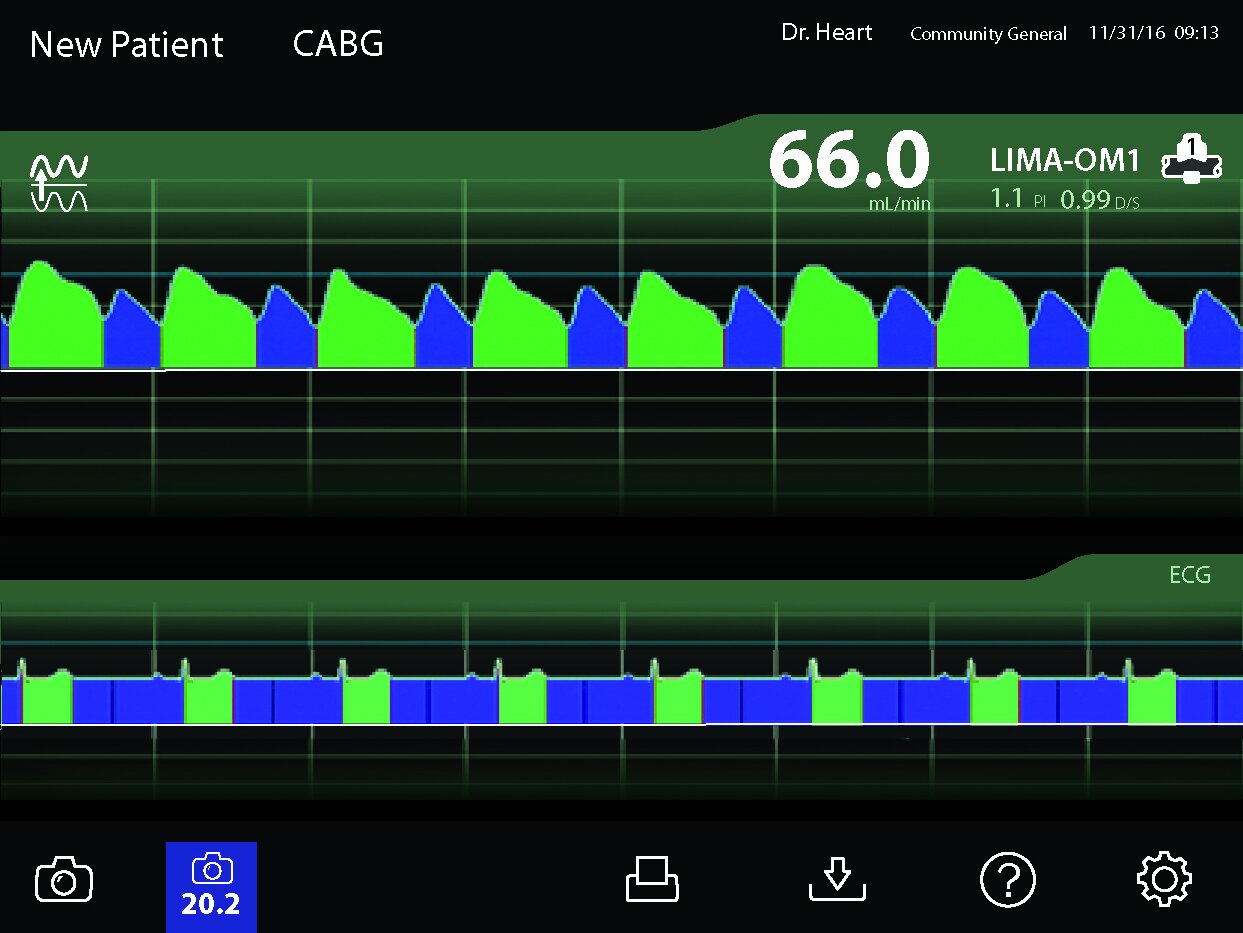

Our work began with ergonomic studies to develop a component layout that would allow surgeons to see the data from the sterile field while the circulating nurse or perfusionist managed the operation of the system. The meter needed to function as a standalone device or be mounted on a cart with a rotating secondary display, a printer, and storage for supplies.

CONCEPT DESIGN

Using the knowledge gained in our research, we developed multiple design concepts. In a parallel effort, we defined the user interface for the touchscreens on the meter and the surgeon’s display. These were then incorporated into our next round of market research.

Brownlie Design again teamed up with RMS to create an online survey for users to evaluate the concepts and select the preferred design for the flowmeter. As CAD work began on the meter, options for the cart were further developed. The printer option needed to be external to the cart so it would be easy to service and replace. This also allowed the cart to be more compact and lower-cost for people who didn’t want an on-board printer.

3D CAD DEVELOPMENT

Another goal of the new design was to reduce manufacturing time. Brownlie Design worked closely with Transonic Engineering to develop an assembly process of stacking from the front to the back without reorienting the housing during the assembly process. The development of the cart required collaboration with suppliers to ensure structural integrity and appropriate tolerances that would mate well with the plastic skins. Part break up and wire routing was designed to simplify the assembly required by the customer and reduce shipping costs

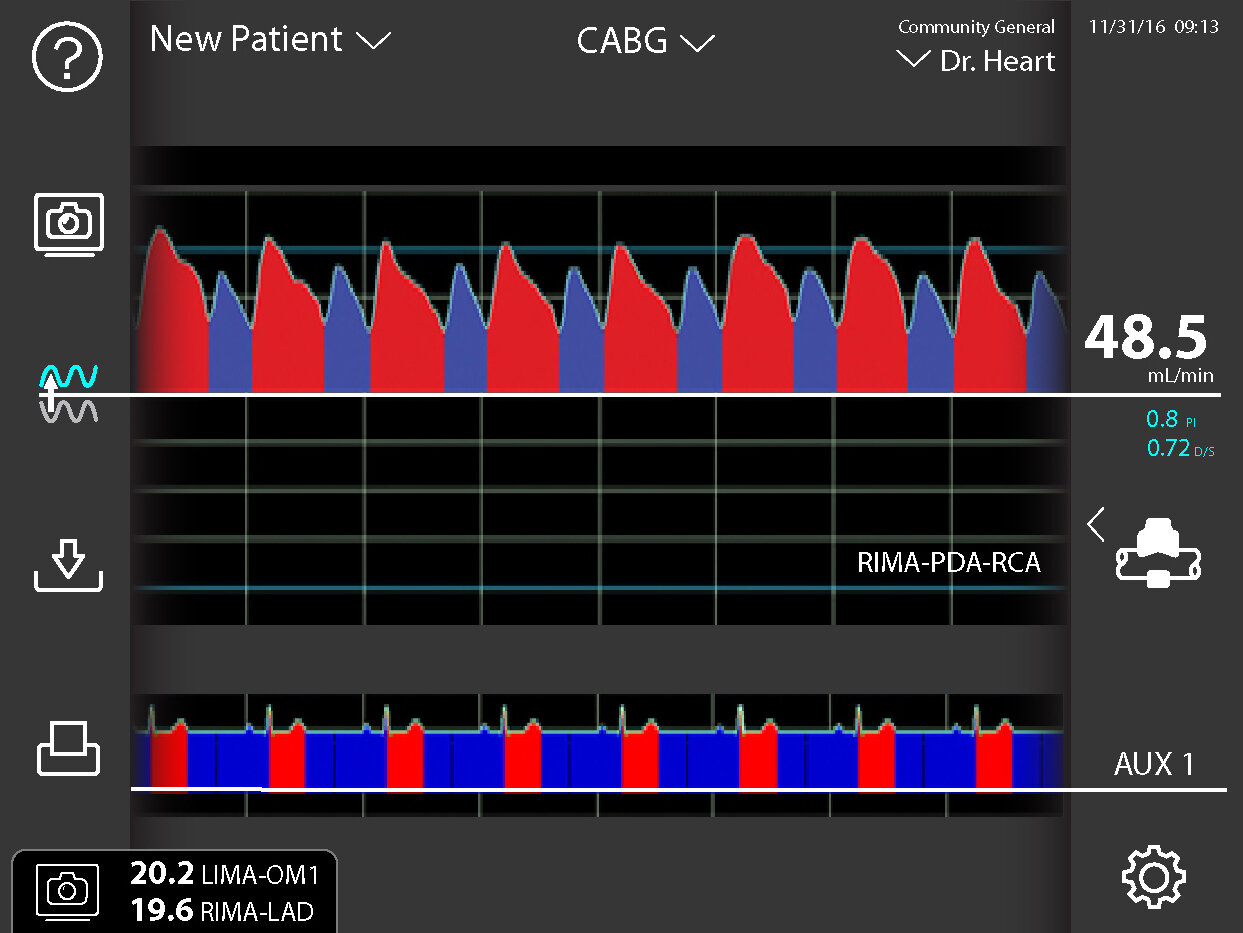

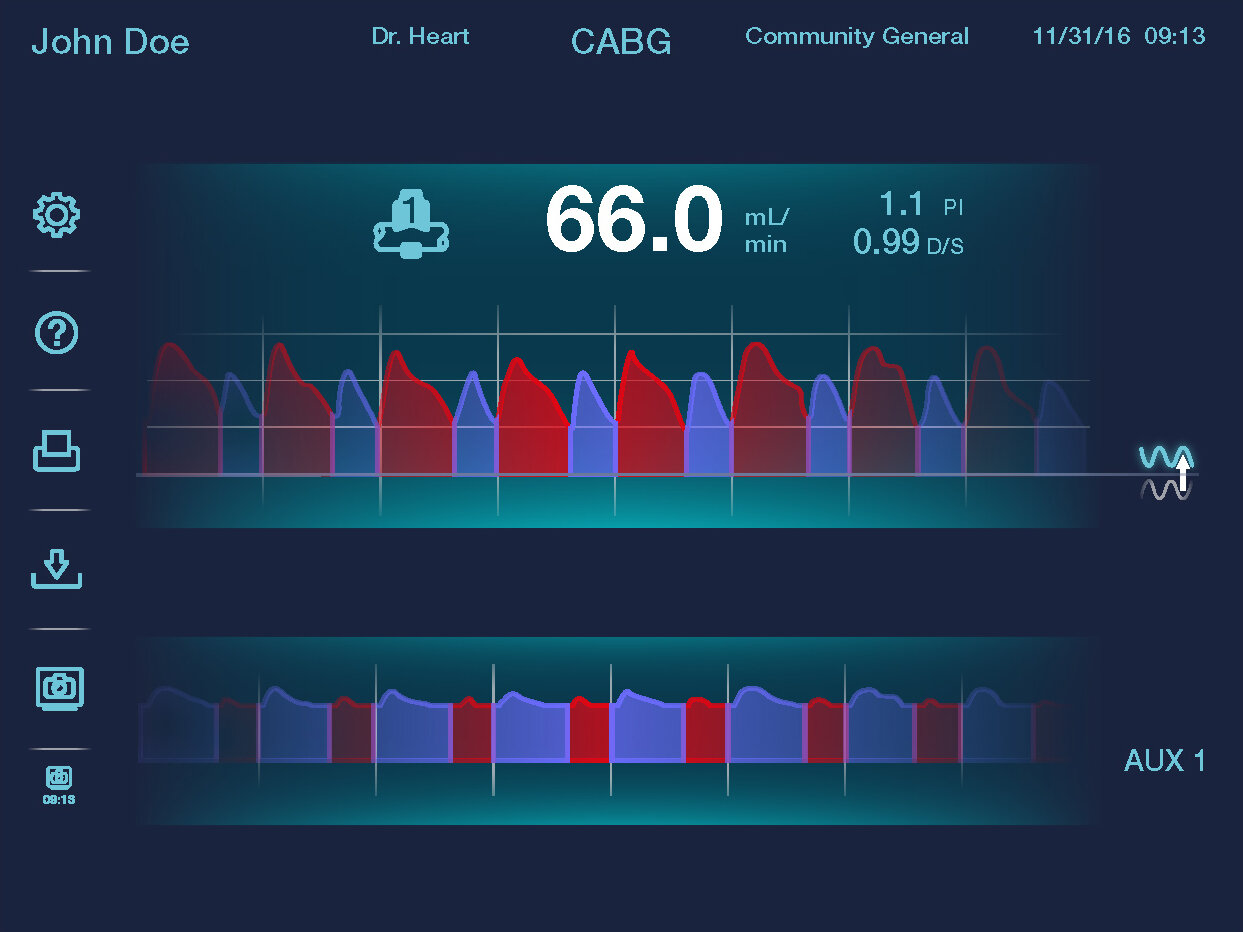

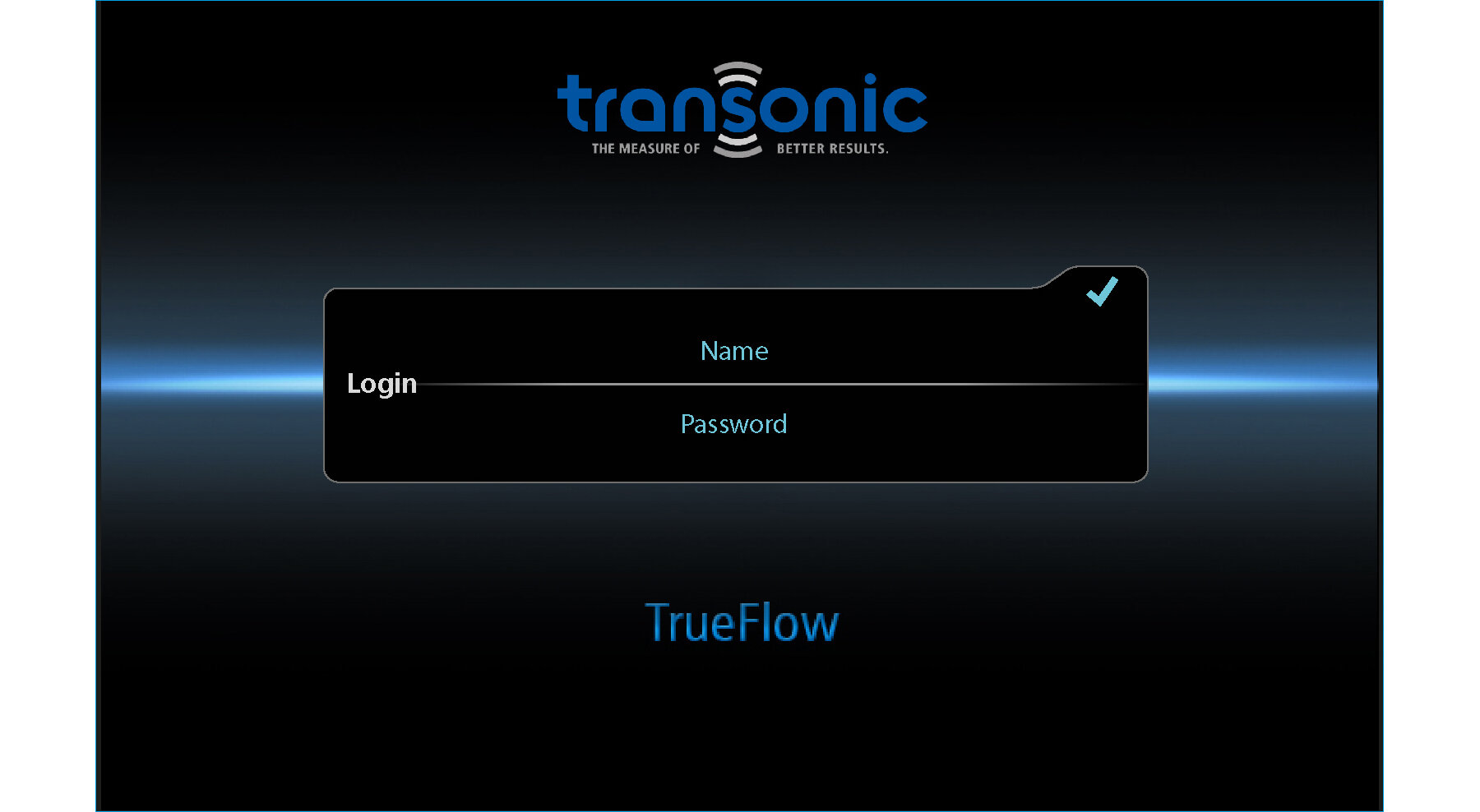

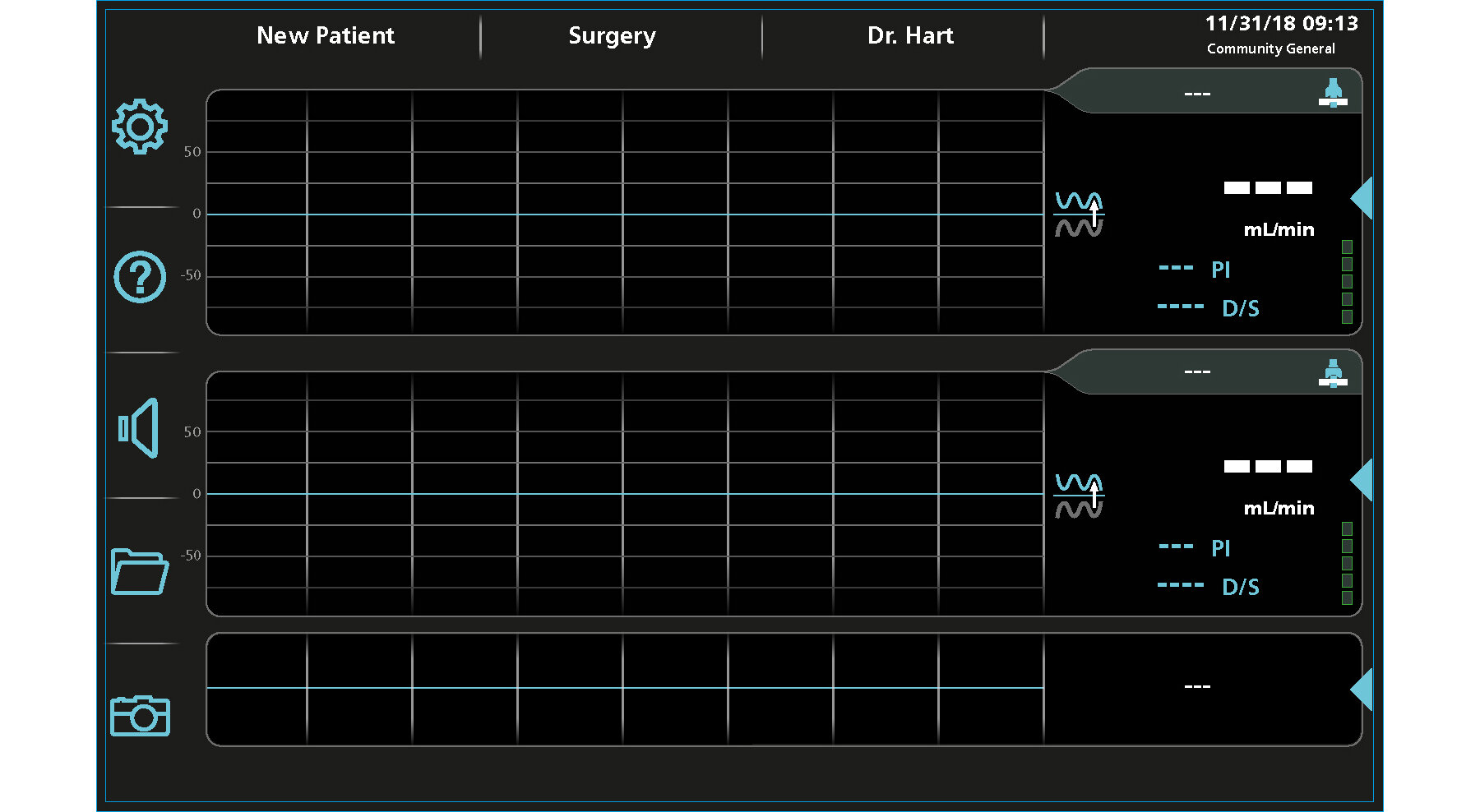

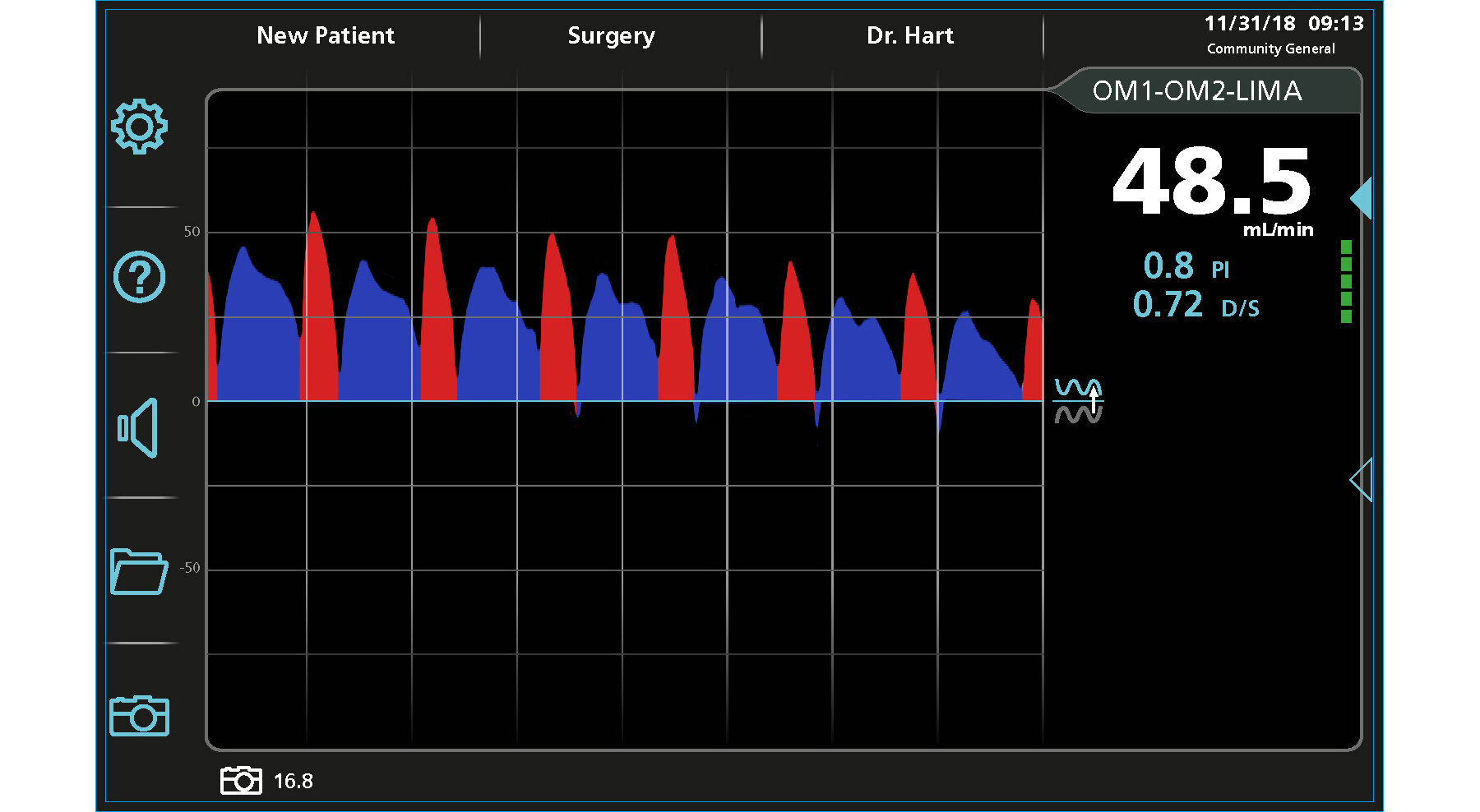

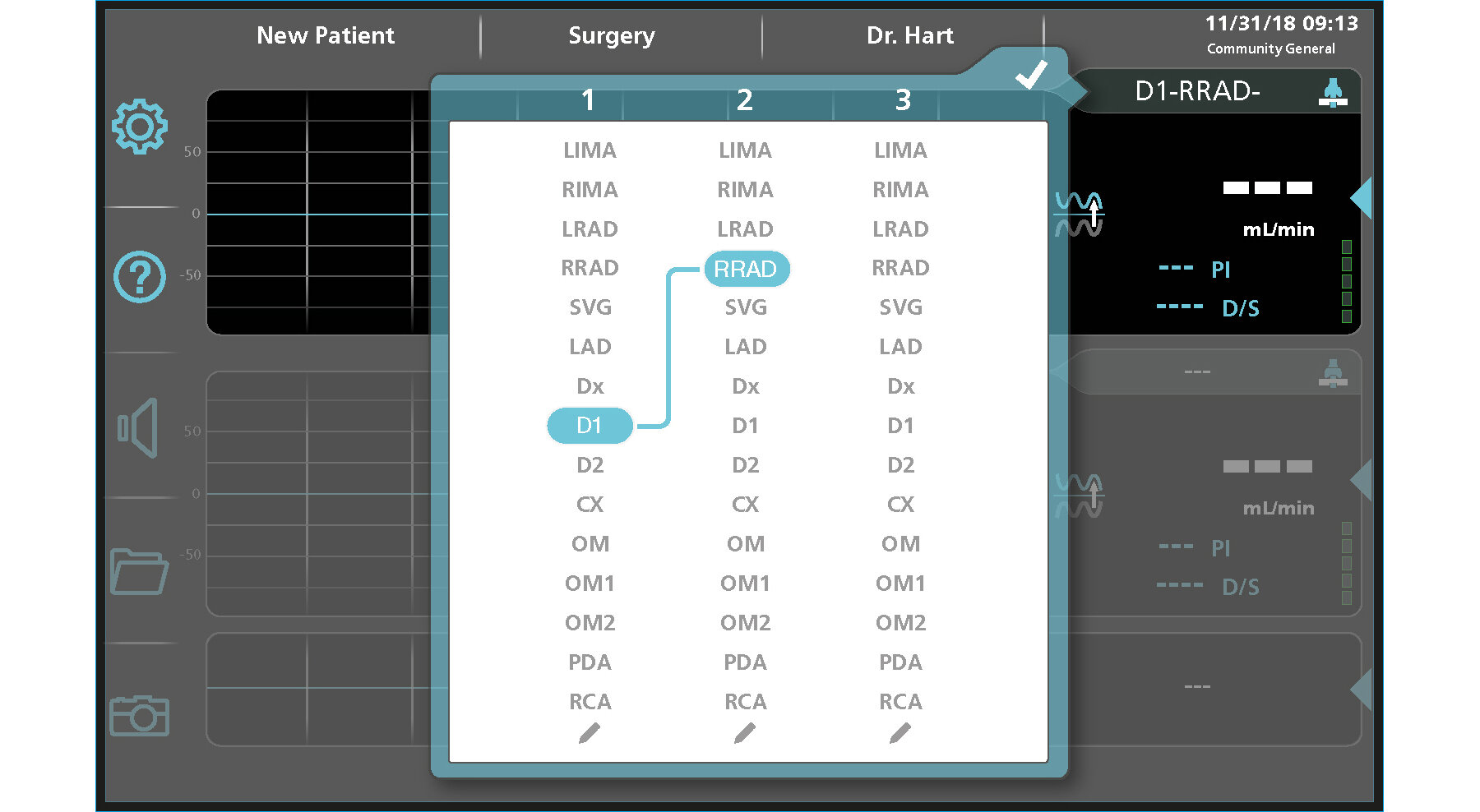

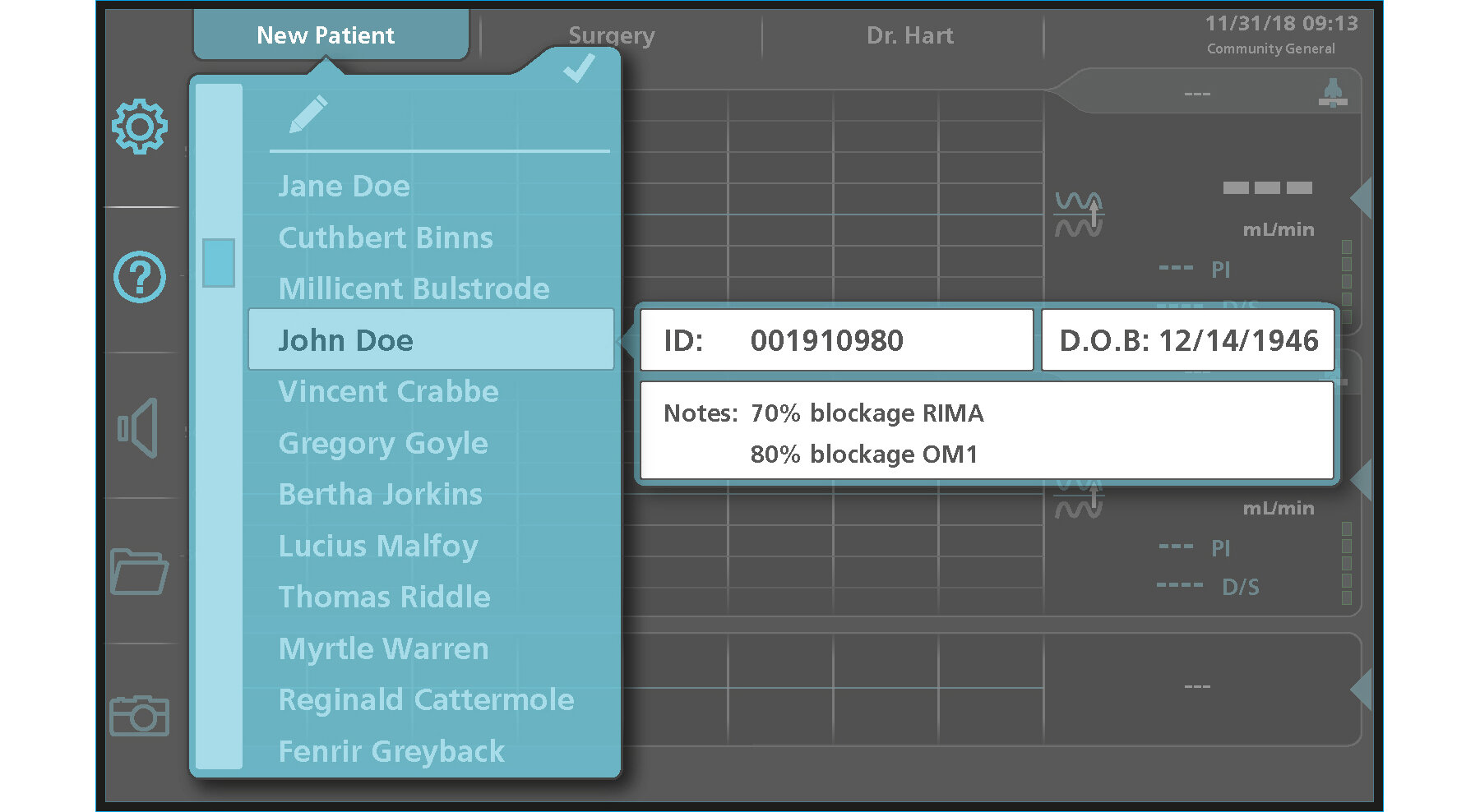

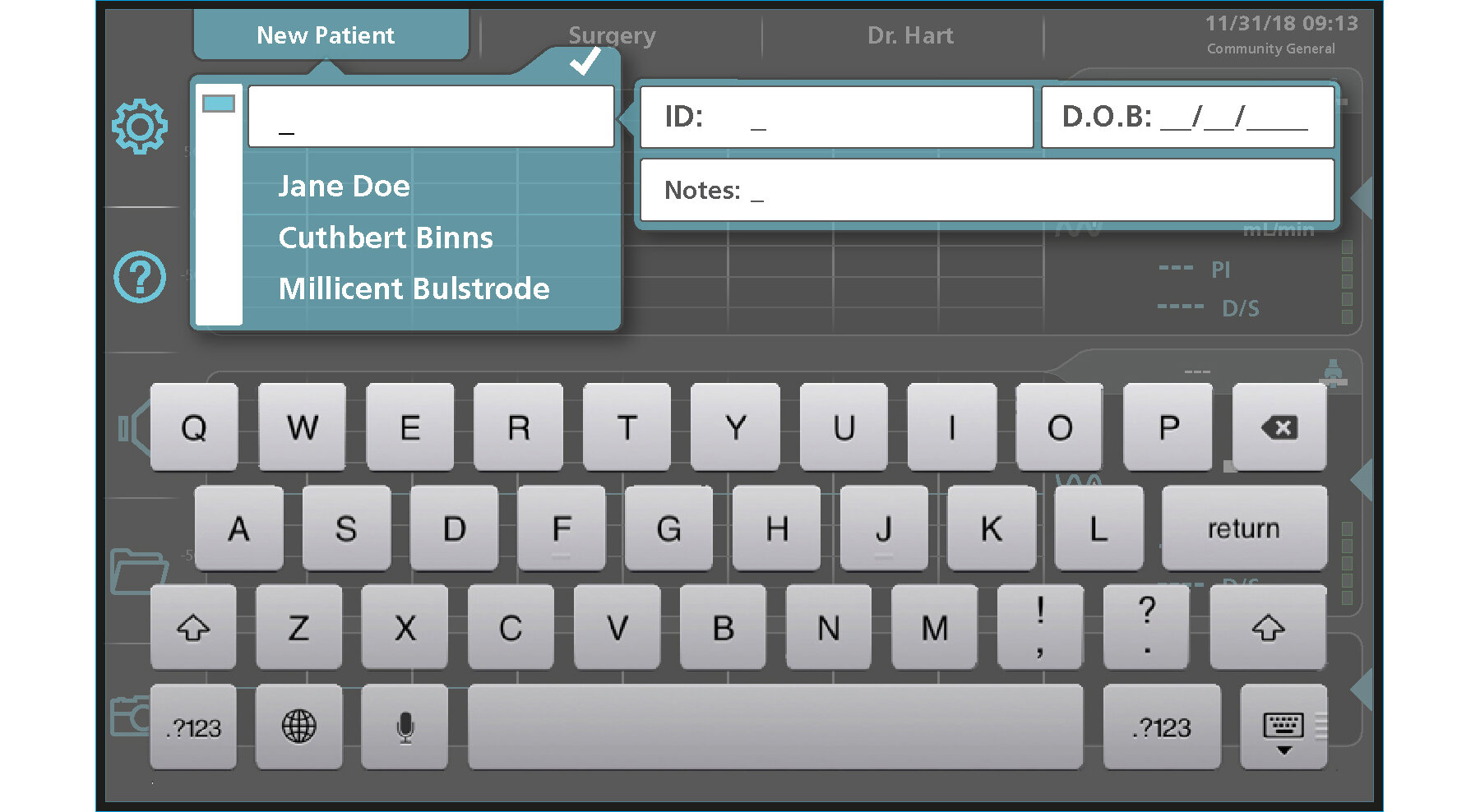

UI DESIGN

Brownlie Design established the touchscreen appearance and icons as well as the top-level navigation. The final execution was completed by Transonic’s in-house team.

PROTOTYPING

Using a combination of 3D-printed parts, CNC machining, and fabricated sheet metal, a prototype was constructed to verify assembly, fit, ergonomics, and aesthetics.

With its simple operation, scalable hardware, and intuitive user interface, the Transonic Flowmeter has been well received in markets around the world.